Welcome to FCY Hydraulics!

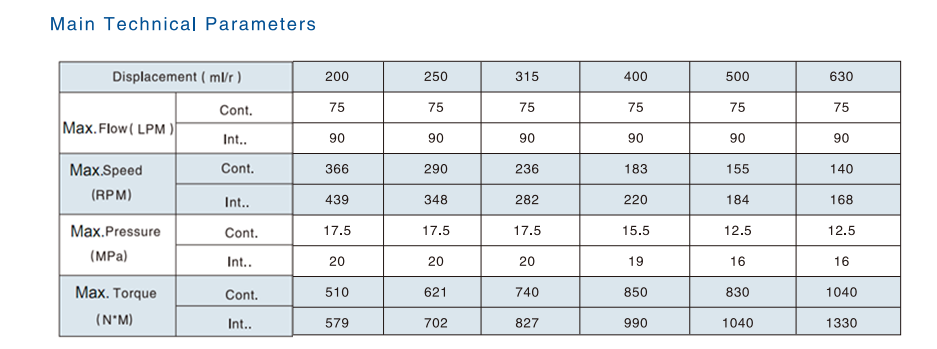

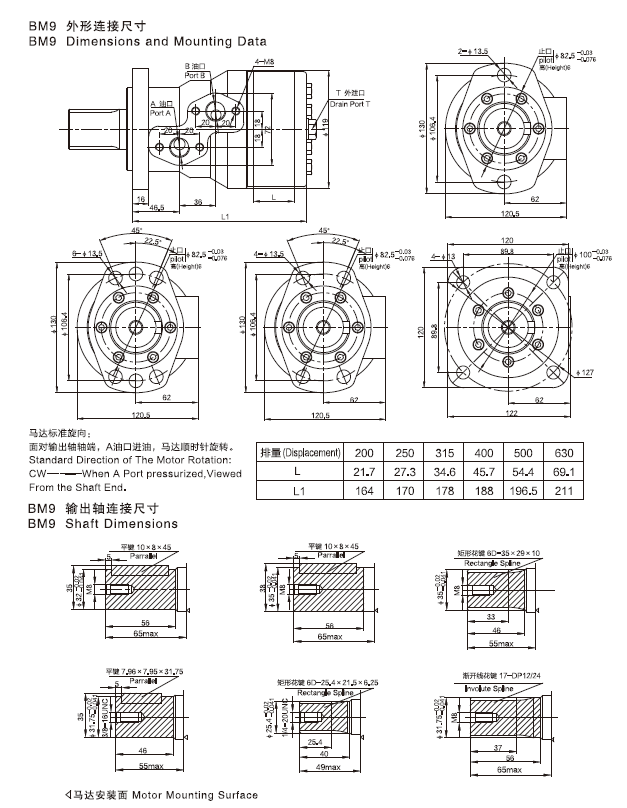

China Manufacturer of High Speed Hydraulic Motor BM9 Series

Characteristic Features:

- It adapts the gerolor design, which has a higher oil distribution accuracy and mechanical efficiency

- Rolling bearing design , which has a greater lateral load capacity

- Reliable shaft seal design, which can bear higher pressure and be used in parallet or in series

- The forward and reverse direction conversion is convenient and the speed is stable

- A variety of connection types of flange, output shaft and oil port.

In order to make the BM1, BM2, BM3, BM4, BM5, BM6, BM7, BM8, BM9, BMM orbit hydraulic motors work in the best condition, we recommend:

- Oil temperature: Normal working oil temperature 20℃-60℃, Maximum system operating temperature 90 ℃, (not more than one hour)

- Filter and oil cleanliness: filter filtration accuracy is 10-30 microns, it is best to install a magnetic block at the bottom of the tank to prevent metal particles from entering the system. Working oil and solid pollution level must not be higher than 19/16

- Oil viscosity: the kinematic viscosity is 42-74mm²/s when the temperature is 40 ℃. Hydraulic oil can be selected according to the actual work and the ambient temperature.

- The motors can be used in series connection or parallel connection, when oil return port pressure is more than 10MPa (rotate speed is smaller than 200rpm), pressure relief must be done with the leakage port, it is best to connect the leakage port directly with the tank.

- The output shaft of BM5, BM6, BM7, BM8 and BM10 series motors can bear larger axial and radial loads.

- The optimum operating condition of the motor shall be 1/3 to 2/3 of the rated operating condition.

- For the maximum life of the motor, load the motor for one hour at 30% of the rated pressure. In any case, make sure the motor is filled with oil before loading the motor.

Write your message here and send it to us